Case study

Oil terminal management made seamless

Our customer, a leading European oil company, faced with the complex challenges of today’s oil landscape. The end-users were requiring quality reports, regulators needed to be able to audit the supply chains, and assets had to be monitored in real-time. Additionally, our customer needed to achieve the highest levels of operational efficiency.

We put them at the leading edge of automated processes with a next-generation Terminal and Delivery Management System (TDMS).

Challenge

Our customer, like most players in the oil and gas sector, had found itself caught between two super trends. The unstable price environment meant the company needed to boost the efficiency of its terminals and delivery operations to stay competitive. On the other hand, the process requirements of the business as well as the requirements from stakeholders had suddenly become more complex than ever.

Traceability as an additional challenge

Additionally, as one of the world’s largest producer of renewable diesel, our customer had to cope with enormous variations in composition and quality associated with using a diverse range of biofuel sources. At the same time, they had to meet strict EU regulations regarding traceability and sustainable sourcing.

A new level of automation was clearly the answer. Intelligent, integrated software that could eliminate manual entry, streamline operations and harness the power of IoT would be a true game changer.

Solution

We put the customer at the leading edge of automated processes with a next-generation Terminal and Delivery Management System (TDMS). The main benefit of custom-built TDMS is the near-total level of automation it provides, streamlining the dozens of processes that take place from the moment oil products arrive at the terminal to the point of delivery to retailers.

By digitalizing steps that had been previously handled on paper, our customer can save considerable time and effort while avoiding the human errors associated with manual entry.

Adopting the TDMS also provided our customer with valuable new functionalities that hadn’t been possible before. Real-time monitoring of batch conditions and quality, both at the terminal and on delivery trucks; automated integration of test results from external labs; route planning and guidance for multiple deliveries; and instantaneous billing are some examples of value added. Having information in an accessible, digital format also paved the way for macro-level business analytics and oversight by management.

The TDMS not only provides full supply-chain transparency, it can also predict the precise outcome of each mix of biofuel. It even blocks any loading that would ruin a batch.

Our view: ERP strategy for a new age

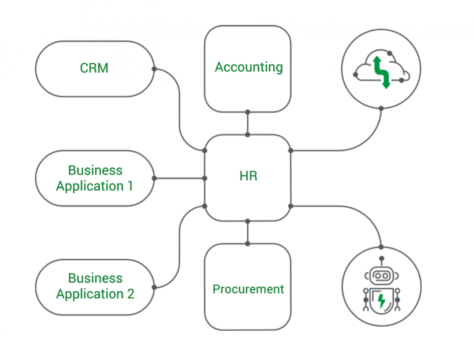

As advancing technology opens up new opportunities for industry, more companies are finding that their all-in-one ERP systems aren’t flexible enough to keep pace. This phenomenon has sparked an interest in what Gartner has termed “postmodern ERP”. A setup whereby ERP systems are scaled back to the core business functions they handle best, leaving operations to be performed by more agile, bespoke systems that are easy to upgrade. This was the strategy we used when creating state-of-the-art TDMS for our customer, new software that is seamlessly integrated with the company’s existing ERP.

15%

increased operating and forecasting accuracy

30%

increase in information accuracy in logistics

93%

time decreased for service action (from 100 to 7 min.)

95%

end-user satisfaction

100%

traceability

Impact

The implementation of state-of-the-art TDMS brought in new functionalities and a higher level of flexibility, making our customer ready to adapt its capabilities to whatever new challenges the market might bring. Building on solid IT knowhow and two decades of experience in the oil and gas sector, we delivered a far-reaching, robust solution to one of the industry’s most significant players. We’re now ready to help other terminal operators achieve the same success, designing systems that leverage the latest available technologies, be it IoT, machine learning or blockchain.

Get in touch

Let us offer you a new perspective.